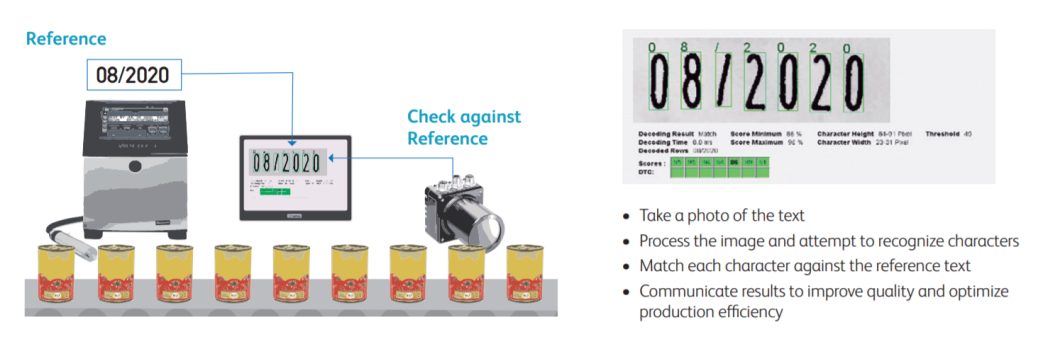

Inline Vision Systems – Videojet 5250 Readability & Validation System

Industrial vision systems bolstered by the simple user interface, precision and proven reliability of Videojet-Laetus. The Videojet 5250 Readability and Validation System helps enable accurate detection of printed text and codes.

Help ensure printed code presence, readability and accuracy.

Seamless integration into your production line.

Improve quality and optimise production efficiency.

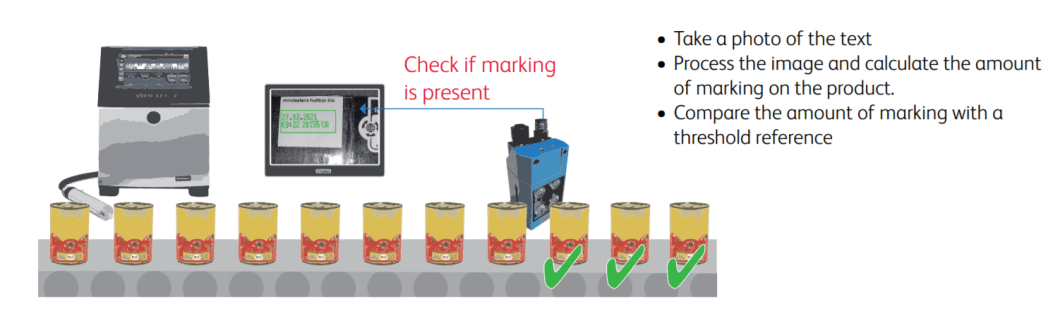

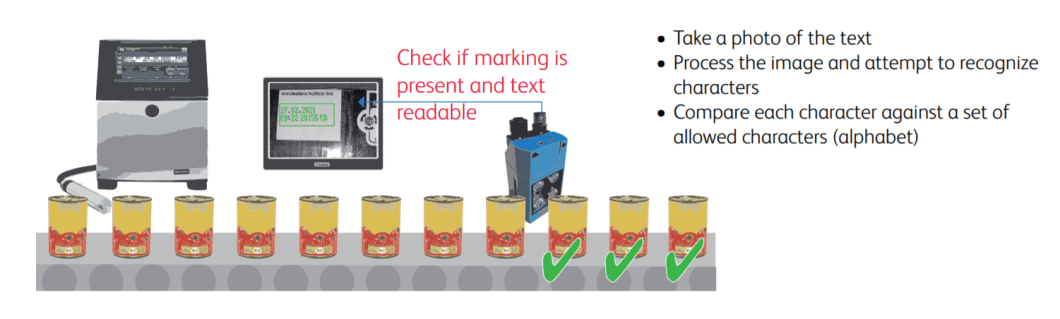

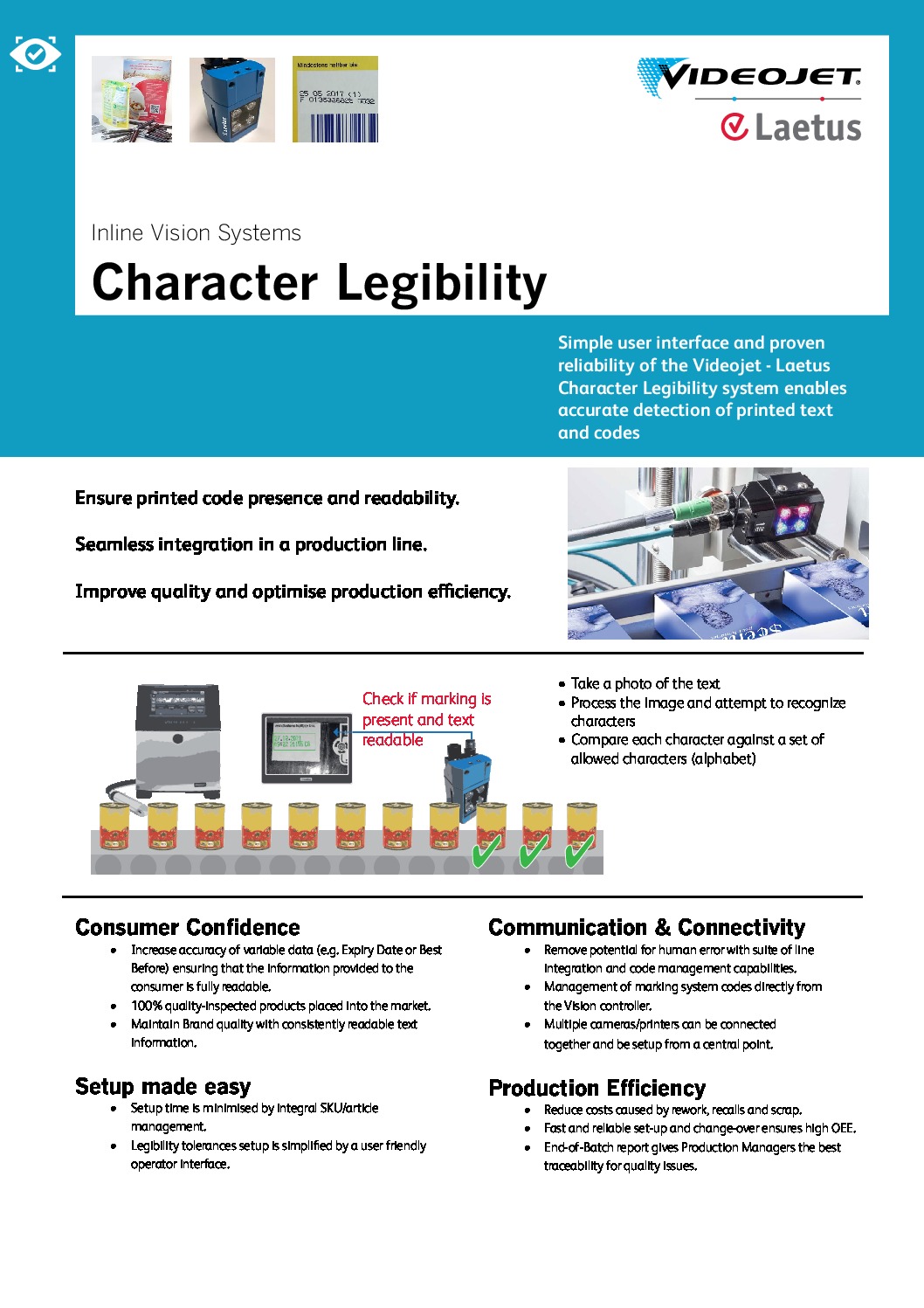

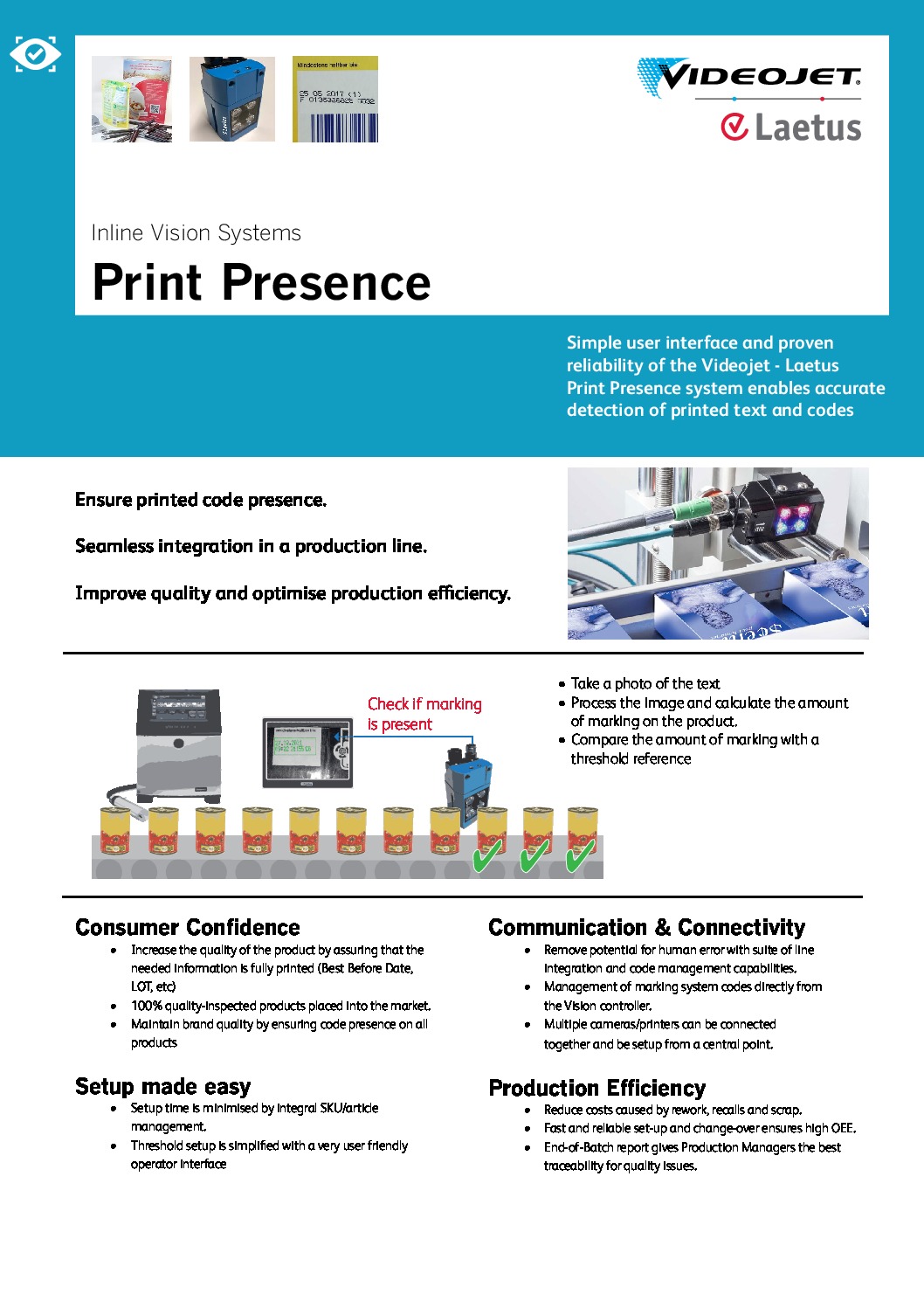

Inline Vision Systems – Videojet 5240 Character Legibility and Videojet 5230 Print Presence Systems

Featuring the same clear user interface and proven reliability of Videojet-Laetus vision solutions, the Videojet 5240 Character Legibility and Videojet 5230 Print Presence Systems help enable accurate detection of printed text and codes.

Ensure printed code character legibility and print presence.

Easy integration into the product line.

Improve quality and optimise production efficiency.

- Overview

- Readability & Validation

- Character Legibility

- Print Presence

Consumer Confidence

- Increase accuracy of variable data (e.g. Expiry Date or Best Before), helping to ensure that the information provided to the consumer matches the product life and is fully readable.

- Increase the quality of the product by assuring that the crucial information is fully printed (Best Before Date, LOT, etc).

- 100% quality-inspected products placed into the market.

- Maintain brand quality with consistently readable and validated text information

- Maintain brand quality by ensuring code presence on all products

Setup made easy

- Setup time is minimised by integrated SKU/article management

- Variable data input is simplified, ensuring the operator only needs to input the data once for printer and camera

- Use of handheld scanners further reduces potential mistakes by scanning work order bar codes

- Legibility tolerances setup is simplified by a user-friendly operator interface

- Threshold setup is simplified with a very user friendly operator interface

Communication and connectivity

- Remove potential for human error with suite of line integration and code management capabilities

- Management of marking system codes directly from the vision controller

- Multiple cameras/printers can be connected together and be setup from a central point

Production efficiency

- Reduce costs caused by rework, recalls and scrap

- Fast and reliable set-up and changeover helps ensure high OEE

- End-of-batch report gives production managers the best traceability for quality issues

- Specification

- Documents

- Video

| Specification | Videojet 5250 Readability & Validation System |

| User interface and software | Laetus NAVIGATOR for MS Windows ARGUS wt10 Server Format database, user management, batch protocol, audit trail, multi device management. COMMANDER 110S, 10” Touch Panel, Windows 10 IoT Enterprise, 128GB SSD |

| Languages | German, English, Czech, Simple Chinese, Dutch, Finnish, French, Greek, Hungarian, Italian, Japanese, Polish, Portuguese, Romanian, Russian, Serbian, Slovenian, Spanish, Swedish, Turkish. Further languages on request |

| Inspection system | SmartSpect camera system, 1280x 1024 Pixel, 131M (monochrome, max. 85 fps) or 131C (color sensor max. 35 fps) |

| OCV/OCR application | Font-based OCR reader, multiple AOI, auto character and row segmentation, max. 64 characters and 5 lines / AOI |

| Bar code application (option) | Omni-directional reading of normal or inversely printed bar code |

| Inspection line speed capability | Depends on application, typically up to 15Hz |

| Lens and lighting options | a) SmartSpect 131M, 12 mm C-Mount lens, protection tubs, requires additional lighting module b) SmartSpect 131M, 12 mm C-Mount lens, DAL white LED bar module c) SmartSpect 131M, 12 mm C-Mount lens, PRL white polarized LED ring module d) SmartSpect 131C, 12 mm C-Mount lens, PRL white polarized LED ring module e) SmartSpect 131M, 12 mm C-Mount lens, DIL white diffuse LED module For available camera field of view, please refer to detailed specifications |

| Environmental protection | Inspection camera IP67 (with lens protection tube), overall protection depends on selected lighting |

| Temperature/humidity range | 0°C to 50°C (32°F to 122°F) 0% to 90% RH non-condensing |

| Electrical requirements | 100-240 VAC at 50/60 Hz. Approx. 60W (24V DC, 240W power supply included) |

| Package options | PRINTER wt, interface software to printing system for synchronized format loading, single data entry for printer and camera, max. 7 data strings, support of GS1 application identifier COCAM wt880, compact 1D/2D bar code reader, WVGA resolution, red/blue LED, 60Hz fps, continuous reading mode, 1 trigger signal, 4 output signals LLS wt580, front or side looking laser scanner, up to 1200Hz, 1D bar code, 1 trigger, 2 output signals |

- Specification

- Documents

- Video

| Specification | Videojet 5240 Character Legibility System |

| User interface and software | Laetus NAVIGATOR for MS Windows |

| Languages | English, Further languages at request |

| Inspection system | Inspector wt621 smart camera system, 1280x 1024 Pixel, monochrome, max. 50 fps, embedded operating system, 1 Trigger input, 3 input signals for future use, 4 result outputs, integrated LED lighting red/blue, LED class 1, strobe control of external lighting, integrated 9.6 mm lens with software adjustable focus, reading distance 70 … 1.500 mm, optical indicators (5x status display, 10x LED bar, 1 green feedback), beeper/buzzer, connectivity prepared for Profinet, EtherNet, EtherCAT, PROFIBUS DP |

| Character Legibility Application | Quality-based character legibility function, adjustable quality and number of character threshold. Configurable print analysis, application tracker tool. |

| Inspection line speed capability | Depends on application, typically up to 15 Hz |

| Working Distance / Field of View | Note! 17.1 mm lens not available! |

| Environmental protection | Inspection camera IP65 Option- stainless steel cabinet IP54 (fan less) |

| Temperature/humidity range | 0°C to 50°C (32°F to 122°F) 0% to 90% RH non-condensing |

| Electrical requirements | 100-240 VAC at 50/60 Hz, approx.. 60W, 24V / DV 240W power supply included 8-port Ethernet Switch included |

| Package options | COMMANDER 110S, 10” Touch Panel, Windows 10 IoT Enterprise operating system, 128GB SSD Electrical cabinet, stainless steel, incl. 24V DC power supply, 8-port Ethernet switch, terminal blocks for 2 inspection cameras, Fault stop signal and indicator |

- Specification

- Documents

- Video

| Specification | Videojet 5230 Print Presence System |

| User interface and software | Laetus NAVIGATOR for MS Windows |

| Languages | English, Further languages at request |

| Inspection system | Inspector wt621 smart camera system, 1280x 1024 Pixel, monochrome, max. 50 fps, embedded operating system, 1 Trigger input, 3 input signals for future use, 4 result outputs, integrated LED lighting red/blue, LED class 1, strobe control of external lighting, integrated 9.6 mm lens with software adjustable focus, reading distance 70 … 1.500 mm, optical indicators (5x status display, 10x LED bar, 1 green feedback), beeper/buzzer, connectivity prepared for Profinet, EtherNet, EtherCAT, PROFIBUS DP |

| Print Presence Application | Contrast based pixel counter, standard or inverse printed style, adjustable acceptance level versus trained reference print, configurable print analysis, application window tracker tool. |

| Inspection line speed capability | Depends on application, typically up to 25 Hz |

| Working Distance / Field of View | Note! 17.1 mm lens not available! |

| Environmental protection | Inspection camera IP65 Option- stainless steel cabinet IP54 (fan less) |

| Temperature/humidity range | 0°C to 50°C (32°F to 122°F) 0% to 90% RH non-condensing |

| Electrical requirements | 100-240 VAC at 50/60 Hz, approx.. 60W, 24V / DV 240W power supply included 8-port Ethernet Switch included |

| Package options | COMMANDER 110S, 10” Touch Panel, Windows 10 IoT Enterprise operating system, 128GB SSD Electrical cabinet, stainless steel, incl. 24V DC power supply, 8-port Ethernet switch, terminal blocks for 2 inspection cameras, Fault stop signal and indicator |